PHARMA

BioReactor – Cooling Agent Transfer

Challenge: A major pharmaceutical company needed a sterile and spill-free solution for transferring cooling agents into their bioreactor systems. Even a small leak could lead to contamination, affecting product quality and leading to expensive delays.

Solution: We implemented DryLink dry disconnect couplings, providing a completely leak-free connection system. These couplings ensured the safe transfer of cooling agents without any risk of spillage or contamination, maintaining the stringent hygiene requirements of pharmaceutical processes.

Result: The company experienced faster, safer operations, reducing downtime due to leakage, while ensuring the cooling agents were safely transferred every time.

FOOD & BEVERAGE

Innocent Smoothies – Leak-Free Transfer

Challenge: Innocent Smoothies was struggling with fluid leakage during the transfer of fresh fruit purées on their production line. Spills created hygiene concerns and costly downtime for cleanup.

Solution: With the integration of DryLink dry disconnect couplings, we provided a secure and leak-free fluid transfer solution that maintained cleanliness and allowed for quick connections and disconnections.

Result: The production process became more efficient, with reduced spillage incidents and increased output, allowing the company to meet growing consumer demand.

Mint Gum – Aroma Containment

Challenge: A leading gum manufacturer faced challenges containing the mint aroma during flavoring transfers. Leaks not only led to product loss but also caused inconsistent flavoring and air contamination, affecting batch quality.

Solution: We installed DryLink couplings to securely seal the transfer lines, ensuring that the mint flavoring remained contained during the entire process. The precision of these couplings prevented leaks, preserving the consistency of the aroma.

Result: Enhanced product quality with a more consistent flavor profile in every batch, while also reducing waste and improving worker safety by minimizing airborne aroma exposure.

Chocolate Refinery – Leak-Free Transfer Operations

Challenge: The transfer of liquid chocolate in a refinery is delicate, as any leak could compromise the product’s texture and quality, leading to costly stoppages.

Solution: DryLink dry disconnect couplings were installed to provide completely leak-proof connections for the transfer of liquid chocolate between production stages.

Result: Production runs were significantly improved, with no leaks or spillage, resulting in more consistent chocolate quality and minimised downtime for maintenance and cleaning

TODO

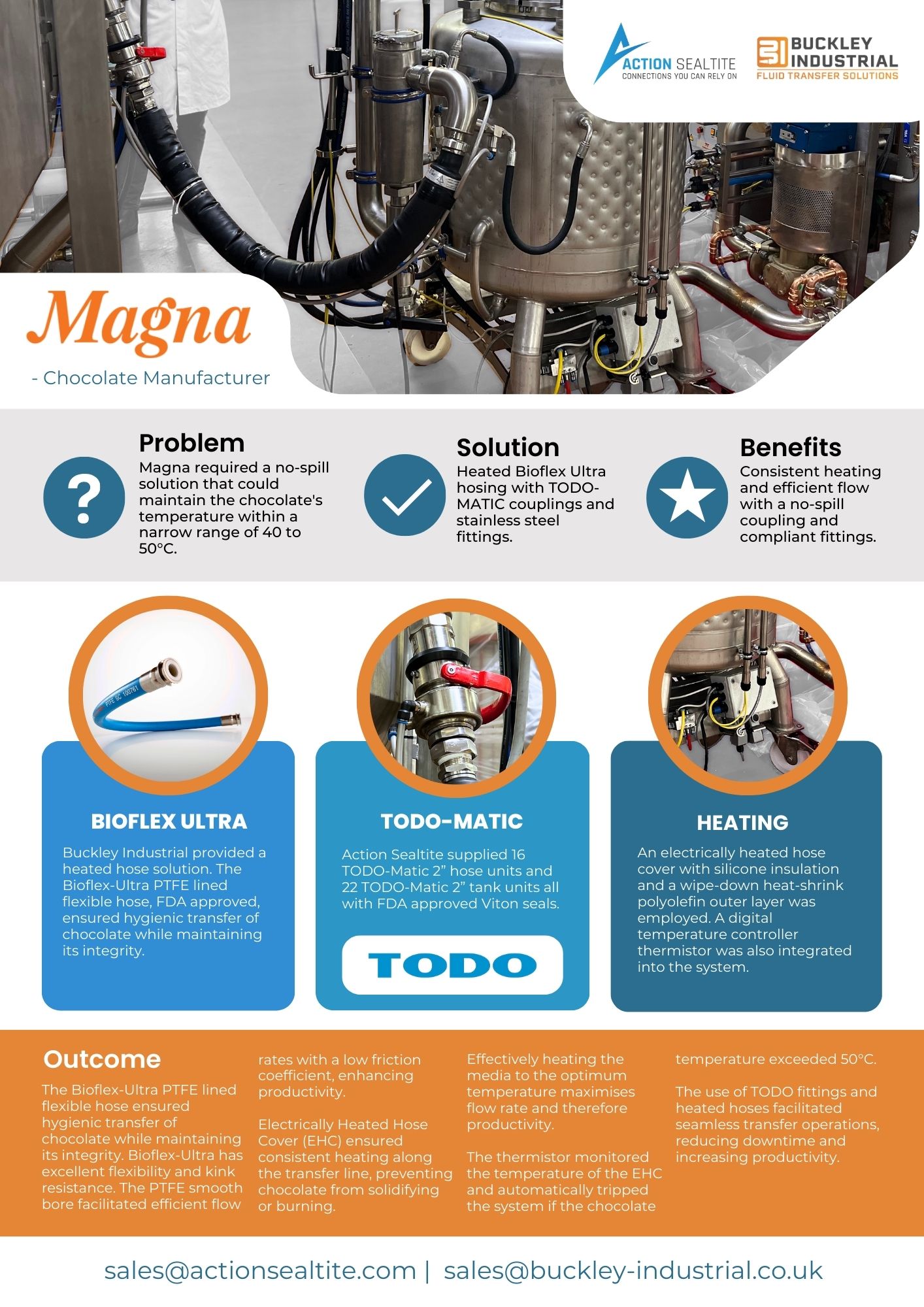

Magna Chocolate – Heated Hosing and Secure Transfer

Challenge: Magna Chocolate, a premium chocolate producer, needed a reliable system for transferring heated chocolate without temperature loss or contamination.

Solution: We introduced a combination of heated hoses and TODO dry disconnect couplings to keep the chocolate at a constant temperature during transfers while ensuring a secure, contamination-free connection.

Result: The temperature of the chocolate was maintained perfectly, and the risk of contamination was eliminated, leading to improved batch consistency and higher product quality.

Milk Spillage – Preventing Costly Drive-Off Damage

Challenge: A dairy processing facility frequently encountered costly milk spillage incidents due to accidental drive-offs during the milk transfer process. These incidents not only led to product loss but also required time-consuming cleaning and equipment repairs.

Solution: A Break-Away couplings which immediately stops the flow of milk in case of a drive-off, preventing spillage and protecting equipment.

Result: The dairy plant would have seen dramatically reduced product loss, saving thousands in wasted milk and equipment repair costs, while also reducing the risk of environmental contamination.