VIEW PDF HERE

Client Profile:

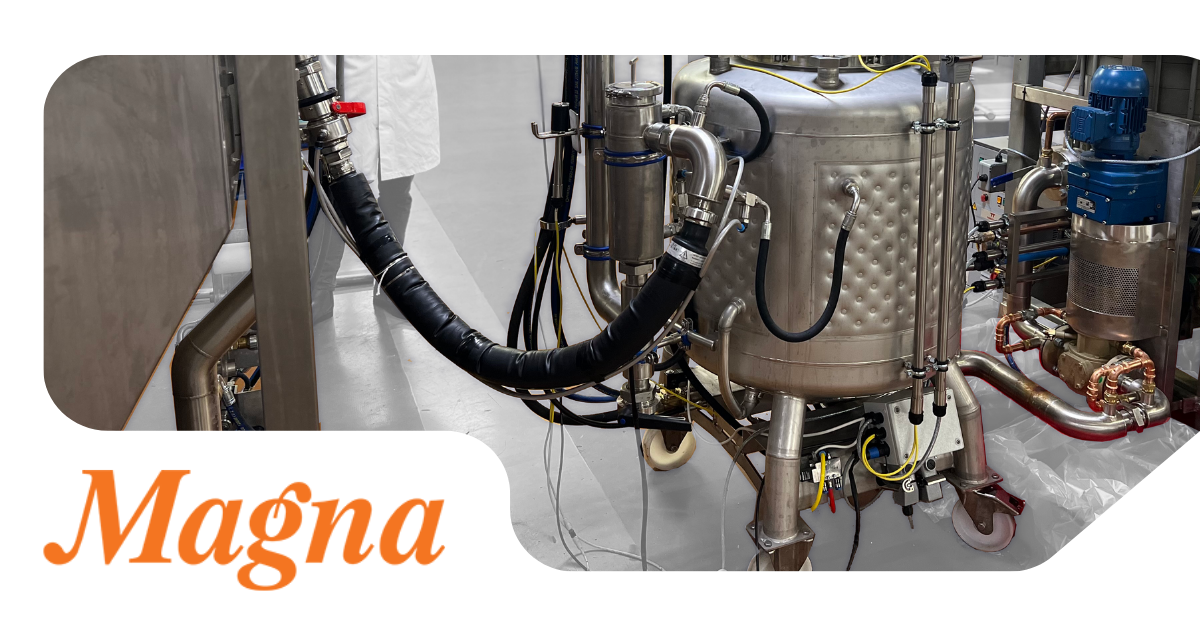

Magna, a renowned contract Easter egg manufacturer based in Telford, Shropshire, specialises in producing hollow seasonal chocolate figures.

The Problem:

Magna faced challenges in transferring chocolate from holding vats to kettle and subsequently to the production line area. They required a no-spill solution that could maintain the chocolate’s temperature within a narrow range of 40 to 50°C. Traditional transfer methods led to spillage, inconsistent temperature control, and potential product quality issues due to overheating or solidifying of the chocolate.

The Solution:

Action Sealtite and Buckley Industrial collaborated to provide Magna with a tailored transfer solution that addressed their specific needs.

- Consultation & Trial Period: Collaboratively, both companies initiated a thorough consultation process with Magna to understand their requirements. A product trial period was conducted to test the effectiveness of the proposed solution.

- TODO Units and Heated Hose: Action Sealtite supplied 16 TODO-Matic 2” hose units and 22 TODO-Matic 2”tank units all with FDA approved Viton seals. and Buckley Industrial provided a heated hose solution. The Bioflex-Ultra PTFE lined flexible hose, FDA approved, ensured hygienic transfer of chocolate while maintaining its integrity. Bioflex-Ultra has excellent flexibility and kink resistance. The PTFE smooth bore facilitated efficient flow rates with a low friction coefficient, enhancing productivity.

- Electrically Heated Hose Cover (EHC): To regulate temperature effectively, an electrically heated hose cover with silicone insulation and a wipe-down heat-shrink polyolefin outer layer was employed. This ensured consistent heating along the transfer line, preventing chocolate from solidifying or burning. Effectively heating the media to the optimum temperature maximises flow rate and therefore productivity.

- Digital Temperature Controller: A digital temperature controller with a sanitary cover was integrated into the system. Equipped with a thermistor, it monitored the temperature of the EHC and automatically tripped the system if the chocolate temperature exceeded 50°C. This eliminated human error in temperature regulation, enhancing product quality and safety.

- Stainless Steel Components: Stainless steel heated metal ring components were utilised to ensure uniform heating throughout the transfer process. All end fittings were made of 316 stainless steel, compliant with FDA regulations, and designed to prevent spillage.

Benefits:

- Improved Product Quality: The precise temperature control ensured that the chocolate remained within the optimal temperature range, minimising the risk of overheating or solidification.

- Enhanced Efficiency: The use of TODO fittings and heated hoses facilitated seamless transfer operations, reducing downtime and increasing productivity. In addition to this, using an EHC is a much more energy efficient method compared to water jacketed/insulated hose.

- Compliance: All components used in the solution were FDA approved and traceable, meeting industry standards for food safety and quality assurance.

- Cost Savings: By eliminating spillage and optimising temperature control, Magna experienced cost savings in material wastage and operational efficiency.

Previous Solution:

Magna’s previous solution relied on spiral water pipe heating with unregulated temperature control. The fittings used were not spill-proof, leading to inefficiencies and potential product quality issues.

Conclusion:

Through the collaboration between Action Sealtite and Buckley Industrial, Magna successfully implemented a comprehensive transfer solution that met their unique requirements. The integration of dry disconnect TODO-Matic fittings, heated PTFE Bioflex-Ultra hosing, and precise temperature control mechanisms resulted in improved product quality, operational efficiency, and compliance with industry standards.