Description

DryLink ® Sanitary Dry Disconnect – The Ultimate No-Spill Coupling

Why Choose Dry Link?

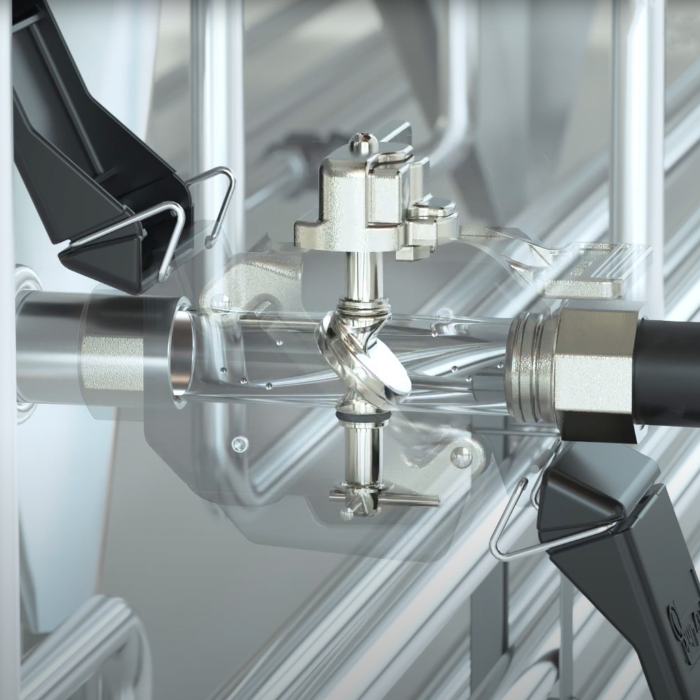

When it comes to dry disconnect fittings, Dry Link ® stands out. Unlike traditional poppet, plunger, or ball valves, DryLink® features a butterfly valve, which offers a more efficient and sanitary solution. Furthermore, with no interior cavities, voids, or springs, it eliminates the risk of bacteria buildup caused by trapped media. As a result, DryLink® is the only true sanitary dry disconnect fitting available today.

The Most Effective Dry Disconnect Coupling

As the market leader in dry break couplings, Dry Link ® delivers unmatched innovation and performance. Its patented design, available exclusively from Action Sealtite, ensures maximum efficiency. In particular, its single-handle operation controls the entire flow, making it the fastest and easiest dry disconnect coupling to use. Additionally, because the handle attaches only to the coupler, it also operates the adapter valve, ensuring a secure and spill-free connection.

Proven Performance – The Only True Non-Spill Coupling

More importantly, DryLink® remains the only true non-spill coupling worldwide. To support this claim, independent third-party testing by Factory Mutual Research confirms that a 2” (DN 50) DryLink hose coupling assembly leaks only 1 to 2 drops after 10 connect/disconnect cycles. By comparison, no other product even comes close! (Source)

Where Can You Use Dry Link?

DryLink works in any application requiring dry disconnection but is most commonly used in industries handling hazardous, toxic, corrosive, or flammable fluids. It is also ideal for transferring high-value liquids. Key industries include:

- Chemical processing

- Pharmaceuticals

- Cosmetics

- Printing & Paints

- Soap & Detergents

- Food & Beverage

- Hygienic & Sanitary Applications

- Nuclear & Microelectronics

Additionally, DryLink fits IBC systems, making it a versatile choice for bulk liquid transport.

What Makes Dry Link ® the Best?

Easy Maintenance – Servicing requires only a pin pusher, hammer, and Allen key. On-site repairs minimize downtime and reduce maintenance costs.

Customizable Options – Choose from a variety of materials, sizes, and finishes to match your specific application.

Superior Safety – Once connected, the valve remains locked. When disconnected, the valve stays sealed, preventing accidental fluid loss.

Efficient Flow – The double butterfly valve ensures full flow capacity, saving time and improving productivity.

Available Material Options

- 316 Stainless Steel – Standard for durability and chemical resistance.

- Alloy 20 (Carpenter 20) – Ideal for sulfuric acid transfers, commonly used in paper mills.

- Hastelloy C – Designed for severe corrosive environments.

DryLink® Seal Options

- Standard: Spring-energized PTFE seals

- Additional Options:

- Moulded Viton (FKM)

- EPDM

- Chemraz/Kalrez (FFKM)

End Connection Options

- FNPT

- British Standard (BSPP)

- Flanged

- Triclover

DryLink® Unit Sizes

Available in 1”, 1.5”, 2”, 3”, and 4” (DN 25, 40, 50, 75, 100). Custom sizes ½” and ¾” are also available.

Pressure & Temperature Ratings

Ratings vary by size and seal material. Contact our team at +44 (0)1235 512500 for expert guidance on the best option for your needs.

What Are Keyed Couplings?

Dry Link ® “keyed” couplings help prevent accidental chemical cross-contamination in batch process plants and manifolds.

Looking for Alternative Dry Break Couplings?

If your application allows for minimal fluid loss and budget is a concern, consider:

Banjo DryMate

Parker 71 Series

Maxi-Dry Dry Disconnect Fittings

For full technical specifications, download our spec sheets or speak with our experts.

📞 Call us today at +44 (0)1235 512500

📧 Email: drylink@actionsealtite.com