Whether it is a ball valve, actuated valve, butterfly valve or any other kind, valves are vital for numerous industries. They ensure that fluids are kept under a controlled flow, and that the flow can be easily stopped and started if needed. But how can you tell if a valve is open or closed?

A valve is considered to be closed when the handle is turned at 90 degrees to the direction of flow. Therefore, when the handle is parallel to the direction of flow, the valve is open. On some ball valves there may not be a handle, in which case, the direction of the flathead screw on the valve can be used as a similar indication as a handle. I.e., if the screw runs parallel to the flow, the valve is open.

Keep reading to find out more about how to tell if a valve is open or closed, as well as some of the different types of valves.

So, What Exactly is a Valve?

A valve is a very simple mechanism. The Oxford English Dictionary defines a valve as ‘A device of the nature of a flap, lid, plug etc., applied to a pipe or aperture to control the passage of air, steam, water or the like…’ Simply put, a valve is a way of controlling the flow of liquid or any media through obstructing its pathway. Valves can be found everywhere, in nature, life, and industry. Even your bathroom taps are valves.

Valves are essential components for numerous industries and many everyday uses across various different applications. At home, in industry, just about anywhere where we need to control the flow of liquids or gases. Valves enable us to ‘shut-off’ supply when it’s not required and then simply re-establish flow as soon as we open them up again.

How do we know if the Valve is Open or Closed?

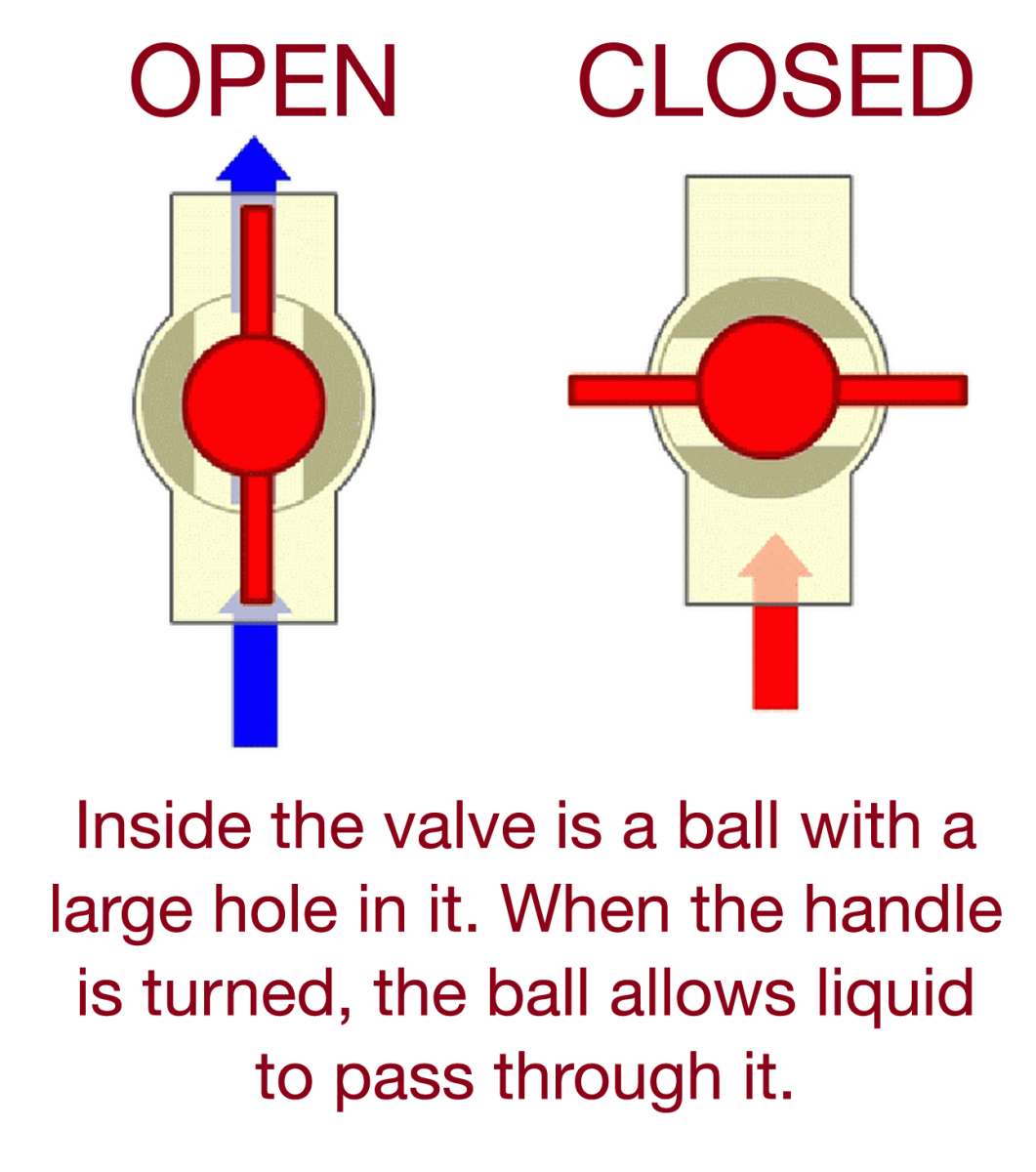

Now we have established what a valve is, how do we know if a valve is open or closed? The majority of valves require a handle to turn the valve from the closed position to the open position. This diagram shows us what this looks like on a simple ball valve.

A Valve Handle’s Position

Usually, when someone asks if a valve is open or closed, they’re not really that interested in the orientation of the valve but what they really want to know is, is there flow passing through? It also may be important to know whether a valve is open or closed before being installed. Otherwise, an open valve installed in error could result in preventable leakages.

In order to tell if the valve is open or closed, the general rule is, if the handle is switched 90 degrees to the flow, it is off. As you can see from the diagram above, if the handle is in line with the flow path, it is on. Simple. Of course, this only applies to manual style valves such as the ball valve in the above diagram. There are exceptions to this rule, such as with actuated valves, which are remotely operated.

Beer pumps don’t look like our diagram but behave in the same way. When the pump handle is pulled down, the valve opens the flow path and instantly releases its sweet divine nectar. Pure joy!

Other Valves Available

Unlike a ball valve, a butterfly valve isolates each end when you separate the coupling. Similarly, a super versatile dry break coupling can successfully prevent any leakage occurring during operation of the valve. Browse the whole range of dry disconnect valves by clicking the button below.

Beer Pumps are Our Favourite Valves

In the example of a beer pump, it is possible for the valve to be in the open position and yet for there to be no flow. Heart breaking! For a beer pump to work correctly the valve needs to be open and a carrier gas (CO2) needs to be flowing into the keg to force the beer out of the other end. If the gas is not connected, there will be no beer, and sadly, we will be calling it an early night!

Submit an Enquiry with Action Sealtite Today

Our full range of high-quality valves and relevant product information are available online for you to browse today.

If you need any further information on any aspect of the points above, please give our knowledgeable sales team a call on +44(0) 1235 512500, complete this form with your name, phone number or email address for a callback, or email us at sales@actionsealtite.com.

Read our full guide to DryLink online today!

FAQs

How do I Know what Type of Valve I Have?

Understanding the differences between butterfly and ball valves is essential for various industrial, mechanical, and plumbing applications. Here’s a guide to help you distinguish between them:

Butterfly Valves

Butterfly valves are quarter-turn valves that use a disk as the flow control element. They are lightweight, compact, and used for quick shut-off in systems with large pipe diameters.

Visual Identification

- Disk Inside – A large, round disk is visible when the valve is open. This disk rotates around a central axis perpendicular to the flow.

- Body Shape – Typically, butterfly valves have a slim, cylindrical body with flanges on either side for connection to the pipeline.

- Handle/Lever – Manually operated butterfly valves have a lever or gear mechanism for turning the disk.

- Use Cases – Commonly used in water supply, wastewater treatment, and in HVAC systems due to their large flow capacity and low-pressure drop.

Ball Valves

Ball valves are quarter-turn valves that use a hollow, perforated ball to control flow. They are known for providing a tight seal and are used in a variety of applications where reliable shut-off is required.

Visual Identification

- Spherical Ball – The key feature is the ball inside the valve with a hole through the middle. When the hole aligns with the flow, the valve is open; when perpendicular, it’s closed.

- Lever Handle – Most ball valves have a long lever handle that, when aligned with the pipe, indicates the valve is open, and when perpendicular, it indicates it is closed.

- Body – Ball valves usually have a more robust body, often with a slightly bulged section where the ball is housed.

- Use Cases – Ideal for applications needing a tight shut-off, such as gas pipelines, oil lines, and water systems.

Understanding these differences will help you correctly identify and select the appropriate valve type for your specific needs. Get in contact today and let us help you!

Where Shouldn’t Ball Valves Be Used?

Ball valves are often preferred to gate or globe valves due to their ease of use, but they can lack the fine control required in throttling applications. They can also be problematic when it comes to cleaning for pharmaceutical, bioprocessing, or food and beverage applications or, if a fitting for non-contamination is required, you may want to explore another option.

If you are unsure and you require a more advanced valve for your operation, please call us for more advice.