Download the Action Sealtite Product Catalogue

Browse the full range of Action Sealtite products by downloading our product brochure today. Included in the brochure is detailed technical information relating to product performance and features, variations, and common applications.

Selecting the Right Coupling

Before purchasing a coupling, it is vital that consideration is given to a number of key aspects that will affect which particular coupling will be suitable for your purposes. These considerations include:

- Flow Requirements – A drop in pressure caused by a lack of consideration given to the flow requirements of a system can affect the performance of the entire line.

- Media Being Transferred – Depending on whether it is a gas or liquid you are transferring, a different type of valve may be required.

- Pressure Requirements – If a system’s pressure is greater than the rating of the fitting, the coupling cannot be used.

- Temperature – This becomes particularly important with regards to material compatibility, as the temperature of the media can affect the material of the fitting.

- Environmental Considerations – Consider the standard operating conditions of the fitting, and make sure you account for the influence of corrosion and cleanliness.

Materials

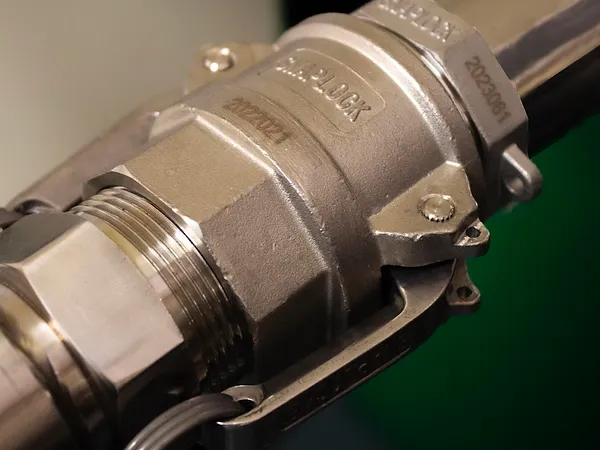

Our SnapTite quick disconnect couplings are available in a range of different materials and sizes to ensure that there is a fitting suitable for a number of applications. SnapTite couplings are available in sizes from one quarter of an inch to four inches, with materials including:

- Aluminium

- Brass

- Steel

- Stainless Steel 316

Valve Types

The valves themselves are available in a number of different combinations, including:

- Straight through (unvalved/plain)

- Single shut-off poppet valves

- Double shut-off poppet valves

If you are unsure what any of these criteria are, please contact a member of our team to be guided towards the right product.

Industries That Use SnapTite Couplings

As SnapTite couplings are highly versatile, they are suitable for numerous applications in a variety of industries. Examples of common applications for these couplings include:

- Hydraulics

- Pneumatics

- General purpose fluid transfer

- Offshore Oil and Gas

Installation and Maintenance

To minimise the risk of costly downtime, we strongly advise that production lines and the equipment in them are regularly checked and maintained. This can help to save money in the long run, as any product with moving parts can become worn with consistent use.

SnapTite FAQs

What Sizes Are Available for SnapTite Couplings?

SnapTite quick disconnect couplings are available in a number of sizes, ranging from one quarter of an inch to four inches.

Are SnapTite Couplings Suitable for High-Pressure Environments?

SnapTite couplings can withstand extreme conditions, and the SnapTite 71 Series Coupler is one of the highest ‘pressure rated’ fittings. This particular coupling is able to withstand pressures up to 10,000 PSI. Find out more about applications for dry disconnect couplings in our detailed blog.

What Do the Different Valve Types Mean?

Below is a brief explanation of each type of valve:

- Straight through (unvalved/plain) – A straight through coupling offers unrestricted media transfer resulting in high rates of flow. This also means that there is little control over the flow.

- Single shut-off poppet valves – A single shut-off valve can be found in the female socket of a single shut-off coupling, which allows the flow of media to be stopped when the couplings are disconnected.

- Double shut-off poppet valves – Commonly used in hydraulic applications, these couplings have shut-off valves in both the male and female connections. This makes double shut-off couplings ideal for both air or fluid transfers.